ROAD ACCESSORIES PRODUCTION LINES

Automatic Line to Produce Base Plate for Column Support

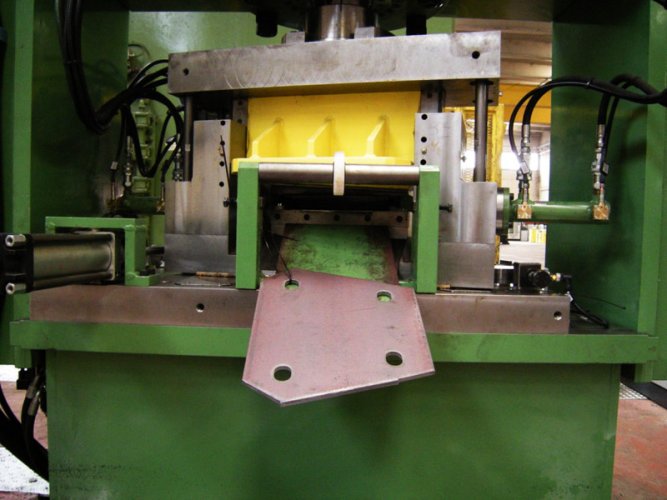

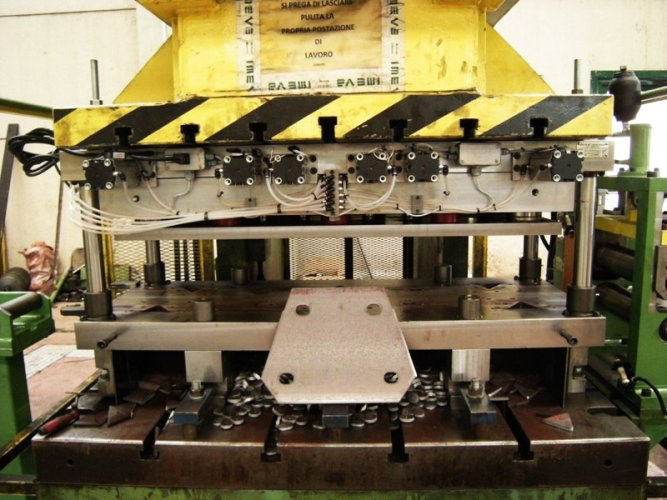

Starting from commercial plate, plate cut and punching, used as base plate for the column support that are mounted on the sides bridge.

AUTOMATIC LINE TO PRODUCE BASE PLATE FOR COLUMN SUPPORT

OMM provide wide and flexible solutions by its latest automatic line to produce base plate for column support.

OMM’s automatic line to produce base plate for the column support can easily be operated and carried thanks to its user-friendly interface.

The pack of the commercial straps is put down carefully on two platforms that lift themselves the same measure of each thickness of the sheet removed, to have every time the same pass-line. Follow two exfoliation groups that transfer a single strap per time on the input roller where the pinch roll takes in charge the sheet and provides to the advancing sheets step by step

Tecnichal and main features

To realize the punching there is a die assembled on the press brake composed by a device to exclude some punches to decrease the punching effort because the target of our machine is to reach the maximum quality. At the end there is a shearing machine with angular rotation to the strap cutting without any kind of scrap and so saving material that means to saving money.

To realize the punching there is a die assembled on the press brake composed by a device to exclude some punches to decrease the punching effort because the target of our machine is to reach the maximum quality. At the end there is a shearing machine with angular rotation for the strap cutting without any kind of scrap by saving material that means save money.

This machine as all our machines/systems has been designed and manufactured respecting all the norms, in term of safety and respecting the environment (noise, fumes aspiration, energy recovery back), given by the European Community:

• Complies with all applicable requirements of the machine directive 2006/42/EC

• Conforms with all applicable provisions of the directive 2006/95/CE (low tension)

• Conforms with all applicable provisions of the directive 2004/108/CE (electromagnetic compatibility)

• Conforms with the standard EN ISO 12100 (General principles on machine design)

• Conforms with the standard EN 60204 (Machine Electrical Equipment)

OMM implement the management system in conformity with the European norm ISO 9001:2015 for the designing, construction, installation and maintenance of the industrial automatic equipment for steel fabrication (EA 18).

- Line starts from commercial plate

- Only one operator for line management

- Production rate: 5 pieces/minute

- Ribbon width: 300 mm

- Sheet max thickness: 10 mm

- Real time data monitoring system & teleservice through internet connection