POLES PRODUCTION MACHINES

Cut to length & trapezium line

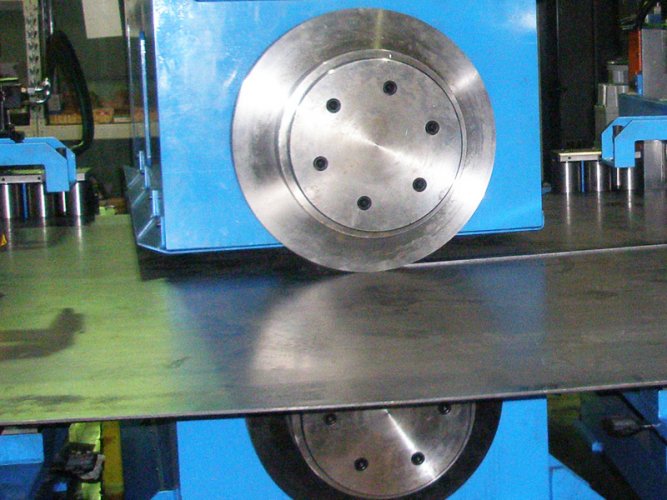

Trapezium cutting, starting from coils.

CUT TO LENGTH LINE

OMM provide wide and flexible solutions by its latest cut to length & trapezium line with flattening & cutting high accuracy and quality, the advantageous high production rate that make very convenient and suitable this machine for poles production plant.

OMM’s cut to length & trapezium line can easily be operated and carried thanks to its user-friendly interface. It’s produced with the latest production technologies able to guarantee the best results in term of flattening and trapezium cutting.

Used for steel poles production, represents the core

machine for companies that want to produce poles with high quality and large production volume.

This machine allows, starting from a wide range of coils in term of weight and width, to flat the sheet without any internal stress providing an optimal cut of the trapezium without any bending. The cut to length & trapezium line, after decoiling provides a blank pre-straightening before entering on the edge trimmer where two couples of circular blades perform the edge trimming. The blank reaches the leveler machine where thanks to the 17 rollers the blank is completely flattened without any internal mechanical stress. Following the shearing machine makes a tilted cutting realizing a parallelogram sheet. The parallelogram reaches the trapezium machine thanks to the roller conveyor where the longitudinal cut is performed realizing two trapeziums that will be divided and stacked on the last part of the line.

Customized cut to length & trapezium line can be designed upon customer request.

Technical and main features

All the process is managed by only one operator for parameters setting and survey, is fully automated without any sheet manipulation. The line needs another operator for coils loading and trapezium packs unloading.

OMM’s cut to length & trapezium line is able to produce trapeziums properly cut in term of length, width and shape for poles production.

Making a well flattening and cutting it’s the main issue for poles production process.

This machine as all our machines/systems has been designed and manufactured respecting all the norms, in term of safety and respecting the environment (noise, fumes aspiration, energy recovery back), given by the European Community: • Complies with all applicable requirements of the machine directive 2006/42/EC

• Conforms with all applicable provisions of the directive 2006/95/CE (low tension)

• Conforms with all applicable provisions of the directive 2004/108/CE (electromagnetic compatibility)

• Conforms with the standard EN ISO 12100 (General principles on machine design)

• Conforms with the standard EN 60204 (Machine Electrical Equipment)

OMM implement the management system in conformity with the European norm ISO 9001:2015 for the designing, construction, installation and maintenance of the industrial automatic equipment for steel fabrication (EA 18).

- Line starts from coils

- Coils diameter up to 2,000 mm

- Coils width up to 2,100 mm

- Coils thickness up to 8 mm

- Coils weight up to 25 tons

- Trapezium length up to 16 m

- Production rate up to 1 trapezium / min

- Edges trimming without rounded edges

- Scrap reduction & material optimization

- Sheet flattened without internal mechanical stress with no trapezium cambering

- Real time data monitoring system & teleservice through internet connection

- Only one operator for line management + 1 operator for coils loading and trapezium pack unloading

- Fully automated line able to produce trapeziums sheet directly stocked to the line side