ROAD ACCESSORIES PRODUCTION LINES

Automatic Line for Belts and Chains Production

AUTOMATIC LINE FOR BELTS AND CHAINS PRODUCTION

We call “belts” the straps that connect diagonally the upper extremity of a column support with the lower extremity of the following, while we call “chains” the straps that connect the two-lower extremity of two columns support with lower so differently to the belts the chains become fixed in horizontal.

Both these two products are realized with our special machine without the help of the press brake, so without foundations on the floor that means saving money.

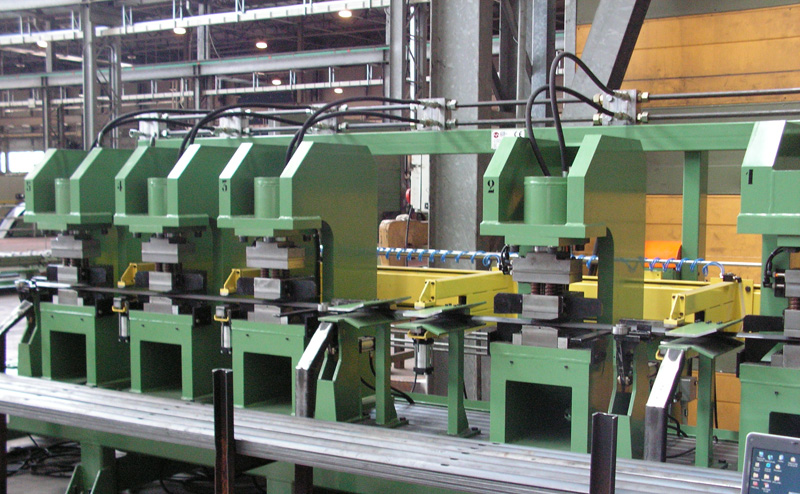

OMM provide wide and flexible solutions by its new automatic line for belts and chains production.

OMM’s automatic line for belts and chains production can easily be operated and carried thanks to its user-friendly interface.

The line is composed by a double decoiler that translates on rails so is possible to load the second coil during the working cycle of the first coil to avoid to stopping time.

Following, the straightener machine with pinch roll to eliminate the blank internal tension due to the coil unwinding, subsequently there are two profiling heads to realize the convexity of the strap and a gauging head to make a perfect final shape.

There is the possibility to mark the belt/chain through the marking unit with hydraulic system that allows to realize the selected wording.

Tecnichal and main features

By buying this line from OMM, the advance that we offer compared to our competitors is that our line doesn’t needs a big press and foundation because is composed by a little hydraulic unit for the punching and cutting.

At the end there are the picking groups constituted from arms that provide to move the belt/chain already punched under the bending unit for tapering in order to taper both extremity and the same arms provide also to unload the finished product on the unloading table so the package is ready to be stored through forklift.

This machine as all our machines/systems has been designed and manufactured respecting all the norms, in term of safety and respecting the environment (noise, fumes aspiration, energy recovery back), given by the European Community:

• Complies with all applicable requirements of the machine directive 2006/42/EC

• Conforms with all applicable provisions of the directive 2006/95/CE (low tension)

• Conforms with all applicable provisions of the directive 2004/108/CE (electromagnetic compatibility)

• Conforms with the standard EN ISO 12100 (General principles on machine design)

• Conforms with the standard EN 60204 (Machine Electrical Equipment)

OMM implement the management system in conformity with the European norm ISO 9001:2015 for the designing, construction, installation and maintenance of the industrial automatic equipment for steel fabrication (EA 18).

- Line starts from coils

- Only 1 operator for the line management Production rate: 18 sec/piece

- Ribbon width: 40 ÷ 120 mm

- Capacity: 2 Ton

- Coil max diameter: 1,700 mm

- Sheet max thickness: 5 mm

- Real time data monitoring system & teleservice through internet connection