ROAD ACCESSORIES PRODUCTION LINES

Equipment to Produce Corrugated Multiplate

To realize corrugated multiplate through die under press brake with feeding system in automatic.

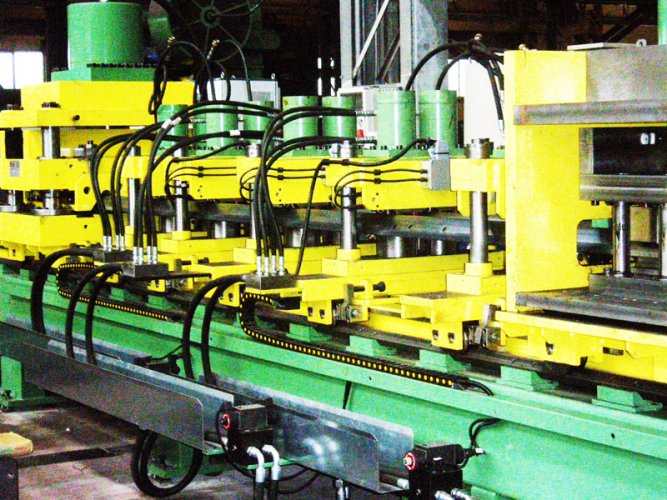

EQUIPMENT TO PRODUCE CORRUGATED MULTIPLATES

OMM provide wide and flexible solutions by its equipment to realize the corrugated multiplate.

OMM’s corrugated multiplate line can easily be operated and carried thanks to its user-friendly interface.

Used for steel multiplate production, represent the core machine for company that wants to produce culverts with high quality and large production volume.

A transfer moves and lifts providing to the sheet a step by step advance in order to realize all the waves.

At the end of the pressing the finished product is the corrugated multiplate that is unloaded and stacked on the lifting platform where will be removed through fork lift operator.

Tecnichal and main features

After the realization of the culverts, the corrugated multiplate become curved, to realize a circumference in more curved parts. To curve the multiplate there are two solutions in base to the customer exigence:

1) by profile bending rolls;

2) by curved die under press brake.

In according with the production rate desired, we are able to customize and give the appropriate solution.

This machine as all our machines/systems has been designed and manufactured respecting all the norms, in term of safety and respecting the environment (noise, fumes aspiration, energy recovery back), given by the European Community:

• Complies with all applicable requirements of the machine directive 2006/42/EC

• Conforms with all applicable provisions of the directive 2006/95/CE (low tension)

• Conforms with all applicable provisions of the directive 2004/108/CE (electromagnetic compatibility)

• Conforms with the standard EN ISO 12100 (General principles on machine design)

• Conforms with the standard EN 60204 (Machine Electrical Equipment)

OMM implement the management system in conformity with the European norm ISO 9001:2015 for the designing, construction, installation and maintenance of the industrial automatic equipment for steel fabrication (EA 18).

- Line starts from sheet

- The line is managed from only one operator

- Wave: 6 or 7

- Thickness of sheet: 2,5 ÷ 8 mm

- Real time data monitoring system & teleservice through internet connection