SPECIAL & INNOVATIVE EQUIPMENTS

Ligthing Pole Profiling Line

Line able to produce lighting poles through roll forming, starting from trapeziums.

LIGHTING POLE PROFILING LINE

OMM provide innovative, special and flexible solutions by its new lighting pole profiling line with high production rate and very innovative way of producing shells that make very convenient and suitable this machine for poles production plant with high production rate.

OMM’s lighting pole profiling line can easily be operated and carried thanks to its user-friendly interface. It’s produced with latest production technologies able to guarantee the best results in term of poles welding.

Used for steel poles production, represent the solution for company that wants to produce poles with very high quality and high production rate, to be successfully on the lighting pole market.

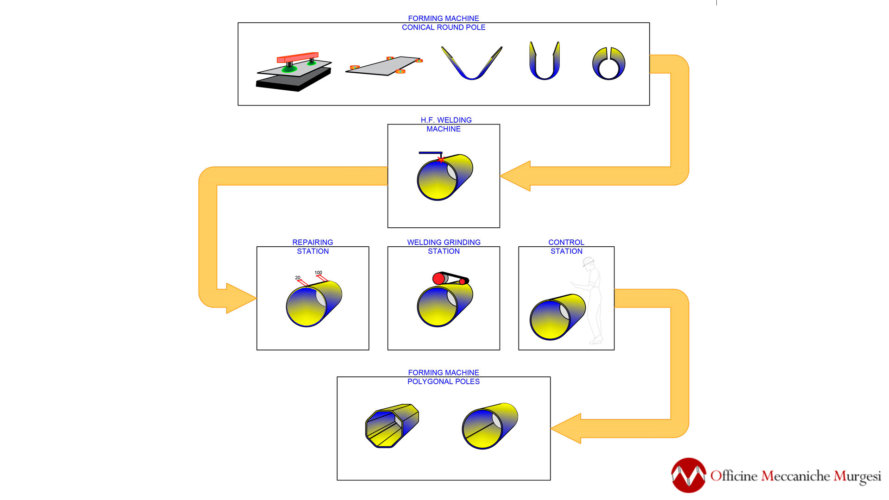

OMM’s lighting pole profiling line realize the profiling of conical round poles starting from trapeziums without the use of press brake. The machine automatically, through its dedicated bridge crane, feed the line, profile the trapezium and make the poles ready to be welded.

Tecnichal and main features

All the process is managed by only an operator for parameters setting and survey, is fully automated without any sheet manipulation. The line needs another operator for trapezium pack loading.

OMM’s lighting pole profiling line change completely the poles production process doesn’t use anymore the hydraulic press brake for the sheet bending and reduce considerably the shell production cycle time.

This is machine is suitable to work in line with the high frequency welding line due to the high production rate.

This machine as all our machines/systems has been designed and manufactured respecting all the norms, in term of safety and respecting the environment (noise, fumes aspiration, energy recovery back), given by the European Community:

• Complies with all applicable requirements of the machine directive 2006/42/EC

• Conforms with all applicable provisions of the directive 2006/95/CE (low tension)

• Conforms with all applicable provisions of the directive 2004/108/CE (electromagnetic compatibility)

• Conforms with the standard EN ISO 12100 (General principles on machine design)

• Conforms with the standard EN 60204 (Machine Electrical Equipment)

OMM implement the management system in conformity with the European norm ISO 9001:2015 for the designing, construction, installation and maintenance of the industrial automatic equipment for steel fabrication (EA 18).

- Line starts from trapezium packs

- Pole minimum diameter 60 mm

- Pole maximum diameter 220 mm

- Pole length up to 13,000 mm

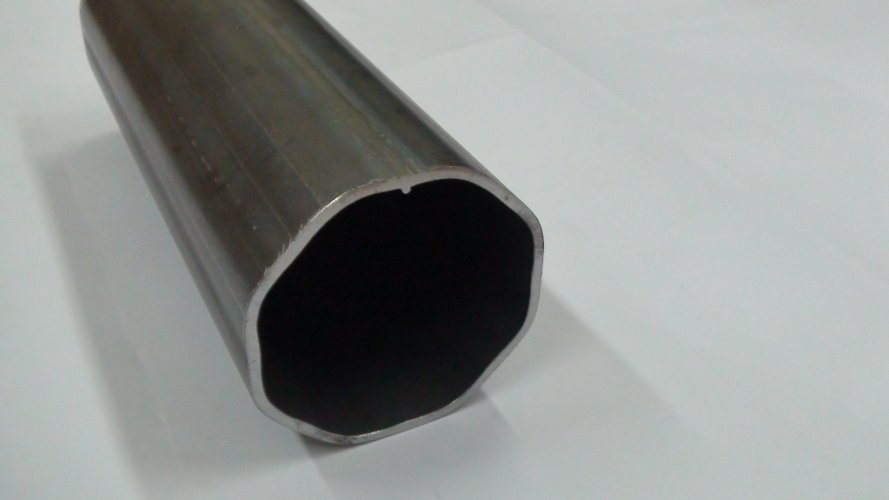

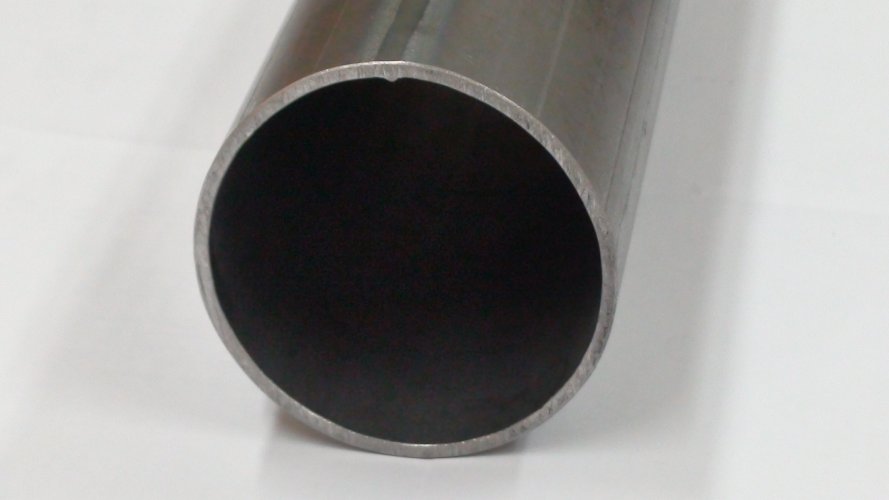

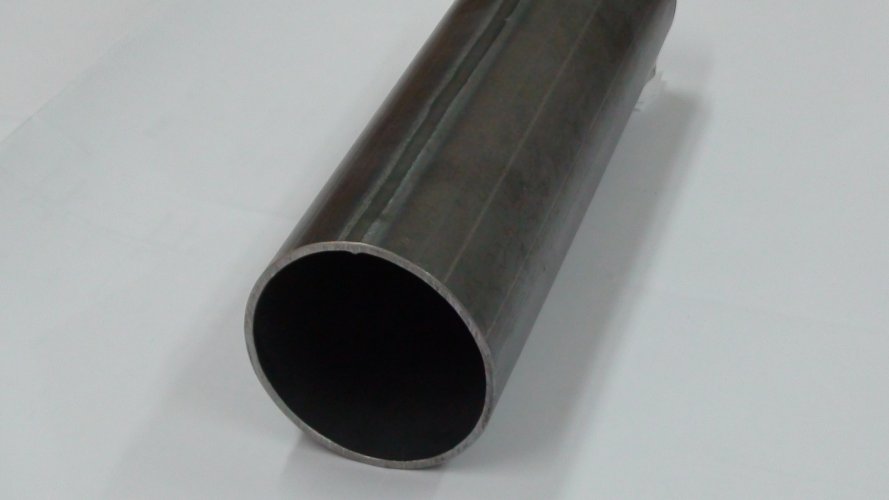

- Pole cross section: conical round & polygonal

- Any pole taper

- Material to process: S235JR, S355JR, S500 (EN10025), without oxide and lubricant, Steel Sheet Levelled, Skinpassed and on-size trimmed

- Line speed up to 18 m/min

- Only one operator for line management & one jolly operator for trapezium pack loading