POLES PRODUCTION MACHINES

Welding Machine for Single & Double Shell Poles

Single shell & Double shell poles welding, starting from bended shells.

WELDING MACHINE FOR SINGLE & DOUBLE SHELL POLES

OMM provide wide and flexible solutions by its latest welding machine for single & double shell poles with an innovative shell coupling system, high quality welding, high welding penetration, conical round & polygonal poles welding, poles straightened, that make suitable this machine for poles production plant with a wide range of poles production typology.

OMM’s welding machine for single & double shell poles can easily be operated and carried thanks to its user-friendly interface. It’s produced with the latest production technologies able to guarantee the best results in term of poles welding.

Used for steel poles production, it represents the solution for companies that want to produce poles (conical round & polygonal poles) with very wide range of poles typology with very high quality, reduced poles handling time and high production rate, covering the production of lighting poles, distribution poles and high mast.

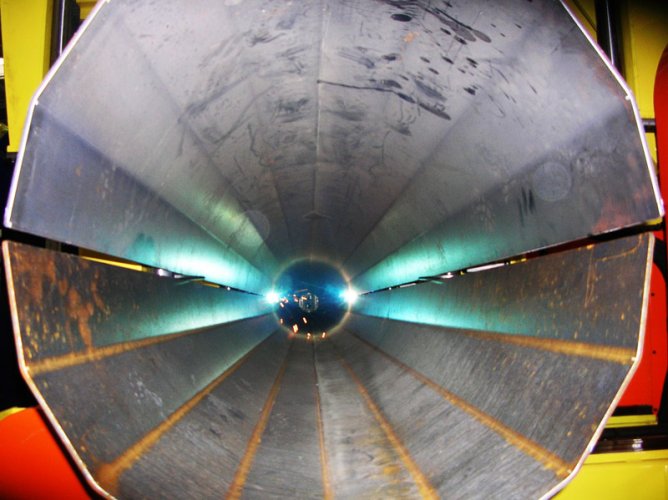

OMM’s welding machine for single & double shell poles process independently conical round & polygonal pole starting from top or bottom as well, up to 1,250 mm of diameter and process single and double shell poles. This machine is suitable for being inserted in an automatic line, downstream of the presses.

The innovative coupling system is fully automatic; the shells are located on two different lines. One of the shells is raised through a cylinder and locked, thanks to the couplers is overturned on the second shell. The pole is pulled in the welding machine in order to start the welding operation. Thanks to its innovative coupling system, no bridge crane or special tools will be required to manage and couple the shells, reducing the coupling time (20 sec), making it accurate and safe.

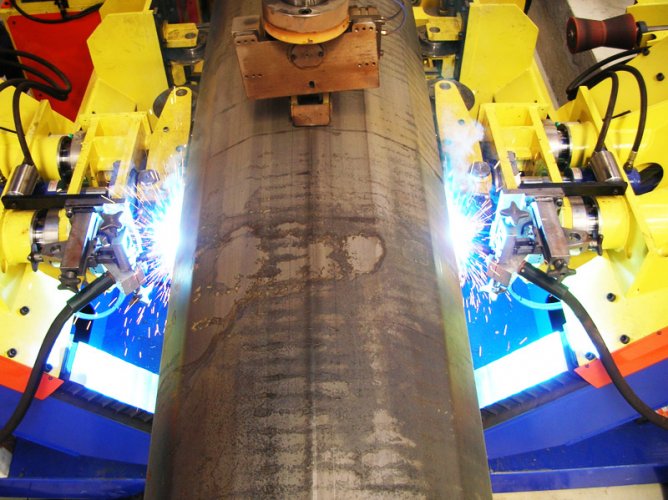

This machine allows, starting from a bended trapezium, to weld the joint applying the proper force from the side and from the top in order to close the joint but without any shape deformation. To make it happen, the machine checks the value of the force applied and change it according to the mechanical resistance (diameter and thickness).

Tecnichal and main features

All the process is managed by only one operator for parameters setting (poles length, top and bottom diameter, thickness) and survey.

Making a good pole, straight and well welded, it’s the main feature in order to don’t waste time and money on the repairing station.

This machine as all our machines/systems has been designed and manufactured respecting all the norms, in term of safety and respecting the environment (noise, fumes aspiration, energy recovery back), given by the European Community:

• Complies with all applicable requirements of the machine directive 2006/42/EC

• Conforms with all applicable provisions of the directive 2006/95/CE (low tension)

• Conforms with all applicable provisions of the directive 2004/108/CE (electromagnetic compatibility)

• Conforms with the standard EN ISO 12100 (General principles on machine design)

• Conforms with the standard EN 60204 (Machine Electrical Equipment)

OMM implement the management system in conformity with the European norm ISO 9001:2015 for the designing, construction, installation and maintenance of the industrial automatic equipment for steel fabrication (EA 18).

- Pole minimum diameter (Single Shell) 70 mm / (Double Shell) 190 mm

- Pole maximum diameter up to 1,250 mm

- Pole length up to 16 m

- Wall thickness up to 8 mm (*)

- Any taper ratio of poles

- Material to process: S235JR, S355JR, S500 (EN10025), Steel Sheet Levelled, Skinpassed and on-size trimmed

- Automatic shell convey without any special tool

- Automatic coupling, pull and welding operation

- Possibility to use the same machine for the single and double shell pole welding

- System for the pole twisting recover (belt)

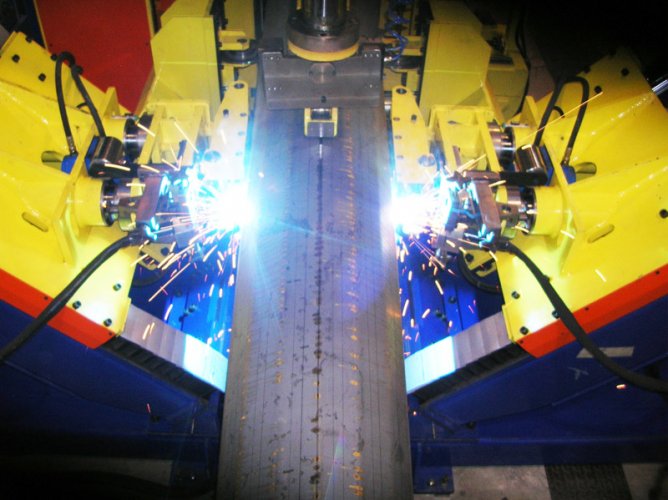

- TWIN SHELL – the steel pole welding with double shell has been done in a single step, without any interruption with the use of two welding torch that weld simultaneously on both sides (left and right)

- Welding Top-Bottom reverse: our machines allows to work starting indifferently from the top or from the bottom diameter

- Conical round & polygonal poles welding MIG/MAG welding technology

- Lateral variable pressure respecting to the pole resistance (diameter and thickness)

- Automatic poles straightening during the welding process, without fire, in case of single shell poles (in agreement with the European law 626/94)

- Minimal poles deformation during the welding phase

- Pull carriage for pole advancement at constant speed making a perfect welding (without any interruption)

- Real time data monitoring system & teleservice through internet connection

- Only one operator for line management

(*) For thickness more than 8 mm, and/or diameter more than 1250, we are able to supply the suitable welding machine as you can see on the following page: Click here

| Thickness (mm) |

Welding speed for Mig-Mag welding technology (m/min) |

||

| Single-shell | Two-shell Two simultaneous weldings |

||

| Penetration 60% |

Penetration 70% – 80% |

Penetration 70% – 80% |

|

| 3 | 2.0 | 1.7 | 1.4 |

| 4 | 1.8 | 1.5 | 1.2 |

| 5 | 1.6 | 1.3 | 1 |

| 6 | 1.4 | 1.0 | 0.7 |

| 8 | 1 | 0.7 | 0.5 |