ROAD ACCESSORIES PRODUCTION LINES

Automatic line for columns / post support production

Line able to produce column support, “U” and “C” shaped, with the same machine.

AUTOMATIC LINE FOR COLUMNS / POST SUPPORT PRODUCTION

OMM provide wide and flexible solutions by its automatic line for columns support production with “U” and “C” profile with high accuracy in the geometrical shape.

The line is automatic with functionality in start-stop, that means that the line starts execute the shape profiling and go ahead until the defined quote where stops and execute the cutting phase & the slots punching and the tapering.

OMM’s profiling line for columns/post support can easily be operated and carried thanks to its user-friendly interface.

The process starts with the coils loading properly trimmed to standard measure that is loaded through the loading cradle on the decoiler drum and can be inserted on the line.

After the decoiler, the sheet is advanced till the shearing machine where is cut, next is flattened and goes ahead reaching the slots punching presses.

The product (column support) presents different typology of holes, slots along its length depending by the model. These holes and slots are realized with the relative dies.

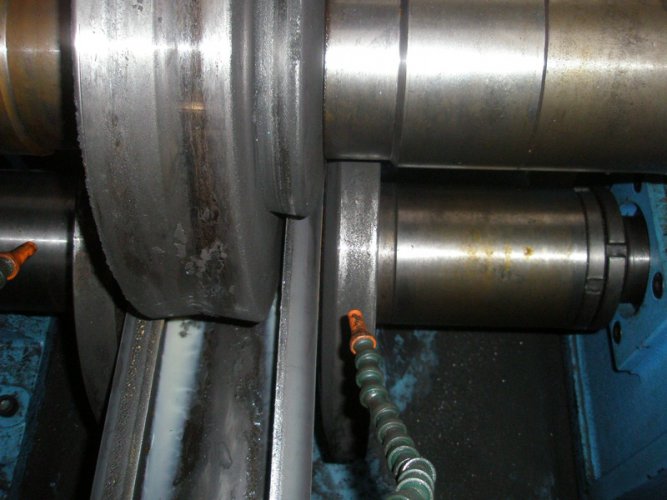

After punching’s operation, the sheet is centered and enters in the profiling roller ready to assume the wished shape.

The profiling group is constituted by heads able to form the column support.

At the end of the profiling phase, the sheet advances inside the column support cleaning group.

Between the profiling heads there is a marking unit (marking wheel) that marks the post in according with the customer wish.

Is it possible to have the same line with working modality in flight.

Customized line can be designed upon customer request.

Tecnichal and main features

The following station is constituted by a cut and tapering unit.

After this step the sheet is called “column support” because has been punched, profiled, cut and eventually tapered. The column support is ready to go on the unloading station.

Through the rotating and the opening of special device the package is made on a hydraulic platform, stacked and ordered with high accuracy.

The column support in that way is ready for the galvanizing.

This machine as all our machines/systems has been designed and manufactured respecting all the norms, in term of safety and respecting the environment (noise, fumes aspiration, energy recovery back), given by the European Community:

• Complies with all applicable requirements of the machine directive 2006/42/EC

• Conforms with all applicable provisions of the directive 2006/95/CE (low tension)

• Conforms with all applicable provisions of the directive 2004/108/CE (electromagnetic compatibility)

• Conforms with the standard EN ISO 12100 (General principles on machine design)

• Conforms with the standard EN 60204 (Machine Electrical Equipment)

OMM implement the management system in conformity with the European norm ISO 9001:2015 for the designing, construction, installation and maintenance of the industrial automatic equipment for steel fabrication (EA 18).

The proposed line is suitable for the production of columns support, for barrier floor anchor, starting from steel coils:

- Line working modality START-STOP (or in flight)

- Coils minimum external diameter: 1,100 mm

- Coils maximum external diameter: 1,800 mm

- Profiling maximum sheet thickness: 6 mm

- Profiling maximum height: 140 mm

- Maximum Tensile Stress: 480 N/mm2 (70.000 psi) + 10%

- Material: roll hot formed steel, galvanized

- Column support length: 1,500÷5,000 mm

- Real time data monitoring system & teleservice through internet connection

- Only one operator for line management